NQBC

Bowen Water Jet Cutting

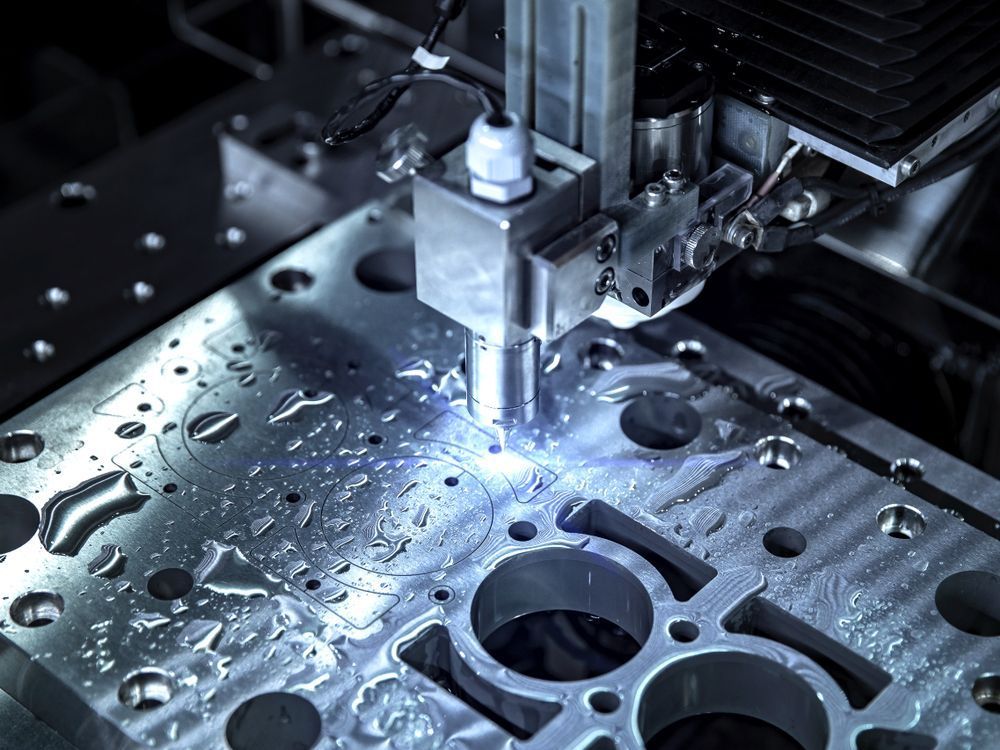

When you need precise, clean cuts without damaging your materials, water jet cutting is the smart choice. At NQBC, we provide expert water jet cutting services in Bowen, using advanced technology to deliver exceptional results for a wide range of industries. Whether you require detailed components, intricate designs, or thick material processing, our water jet cutting process offers smooth, accurate edges without heat distortion or structural compromise.

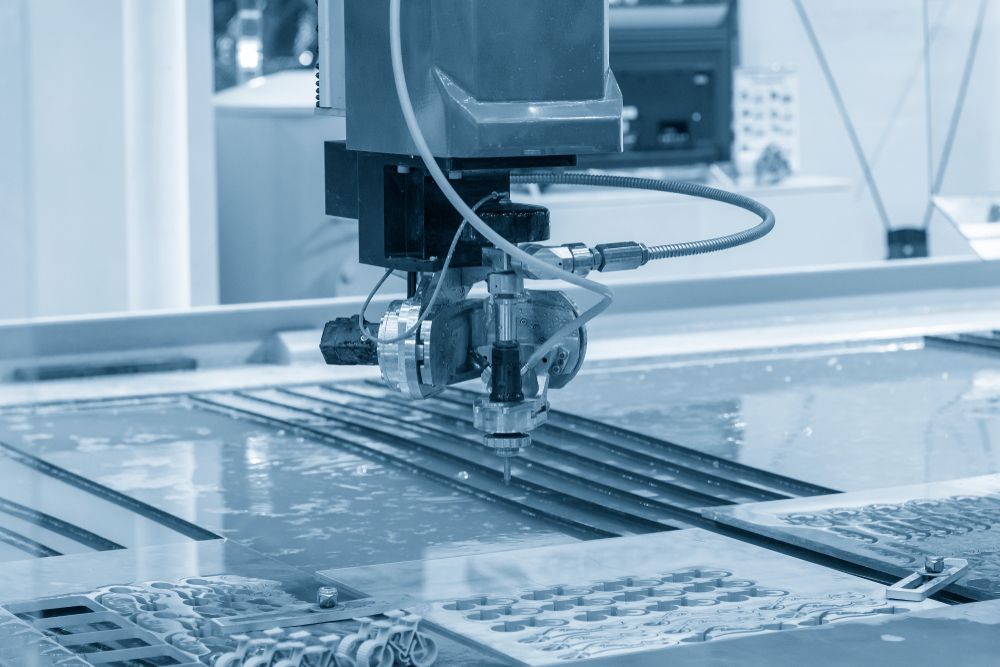

We work with stainless steel, aluminium, mild steel, composites, and many other materials, helping businesses achieve outstanding quality in every project. Our team understands that precision is critical, which is why we focus on delivering work that meets the highest standards for reliability, consistency and durability. Whether it is a one-off project or ongoing production support, we have the expertise and tools to deliver exactly what you need.

Contact NQBC today on 0437 588 078

to discover how our water jet cutting services.

NQBC

High-Precision for Every Project

At NQBC, we use water jet cutting to achieve superior accuracy and clean edges without compromising material integrity. This method is ideal for complex shapes, delicate designs, and thicker materials where other techniques might cause damage.

Our water jet cutting services include:

- Cutting stainless steel, aluminium, mild steel, and a wide variety of other materials with precision.

- Handling custom projects requiring detailed designs, tight tolerances, and smooth finishes.

- Providing reliable results without heat distortion, preserving the strength and properties of the original material.

- Offering fast turnaround times to keep your projects on schedule and within budget.

We are committed to providing the highest quality cutting solutions, whether you need a one-off part or large production runs. Every cut is made with expert care, ensuring results you can trust.

Contact Us in Bowen

Get in Touch

Electrical Service – Contact us

Fabrication Services – Contact us

LOCATION

- Monday

- -

- Tuesday

- -

- Wednesday

- -

- Thursday

- -

- Friday

- -

- Saturday

- Closed

- Sunday

- Closed

After Office Hours: By Appointment (call on 0403 704 679)