NQBC

Ayr Water Jet Cutting

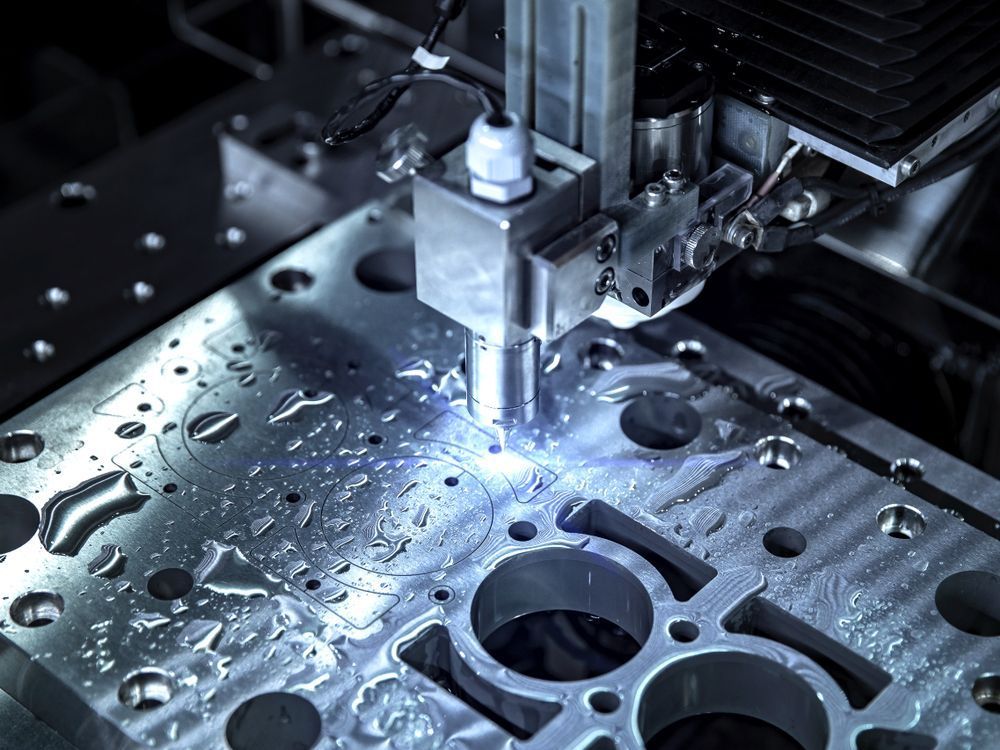

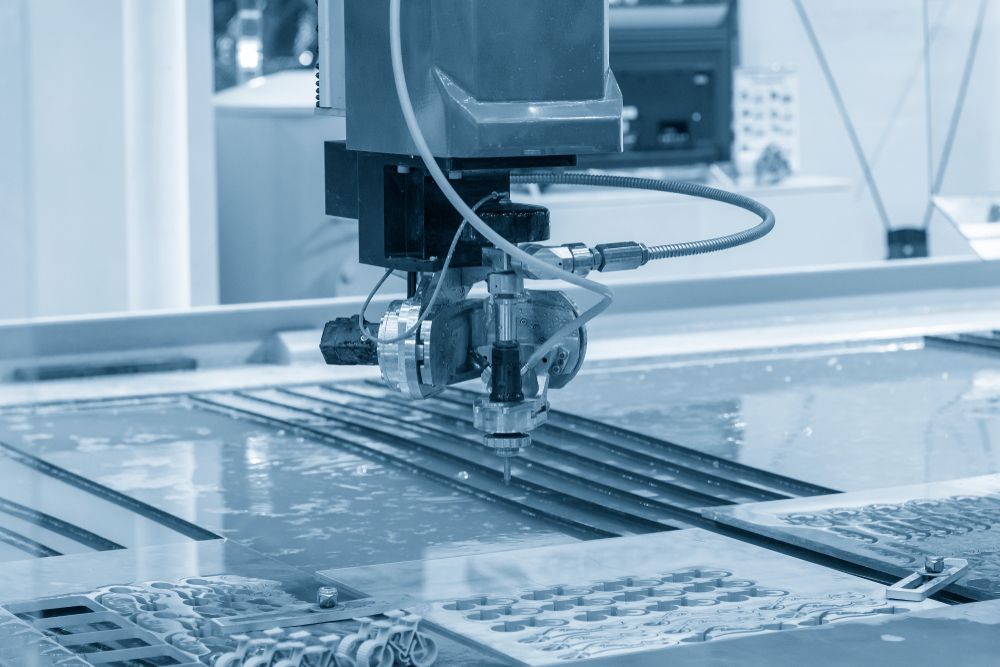

Precision and material protection are crucial when it comes to cutting, and water jet cutting is the method trusted by industries that demand the best. At NQBC, we offer expert water jet cutting services in Ayr, providing clean, smooth cuts across a range of materials without the risk of heat damage. Our advanced water jet technology is perfect for intricate designs, thick materials, and detailed custom work, helping you achieve professional results every time.

Whether you need components for industrial applications, commercial projects, or one-off custom jobs, we deliver accuracy and reliability with every cut. Our experienced team works with stainless steel, aluminium, mild steel, composites, and more to ensure your project is completed to the highest standard.

Contact NQBC on 0437 588 078 today to find out how our water jet cutting services in Ayr can deliver the precision and quality your project demands.

NQBC

Industry-Leading Technology

At NQBC, we combine industry-leading technology with years of experience to deliver water jet cutting solutions that meet the highest standards. Our service ensures your materials retain their strength and appearance, making it ideal for complex and critical projects.

Our water jet cutting services include:

- Cutting stainless steel, aluminium, mild steel, stone, glass, composites, and other materials without heat or distortion.

- Producing detailed and complex shapes with clean edges, requiring minimal finishing after cutting.

- Providing a cold-cutting process that maintains the original properties of the material, preventing stress fractures or warping.

- Offering flexible cutting solutions for both small, intricate jobs and large, heavy-duty projects across various industries.

Our team is committed to helping your project succeed by delivering high-quality cutting solutions that are accurate, consistent and dependable.

Contact Us in Ayr

Get in Touch

Electrical Service – Contact us

Fabrication Services – Contact us

LOCATION

- Monday

- -

- Tuesday

- -

- Wednesday

- -

- Thursday

- -

- Friday

- -

- Saturday

- Closed

- Sunday

- Closed

After Office Hours: By Appointment (call on 0403 704 679)